Food Grade SS316 Rotary Lobe Pumps for Jam Transfer

In the food processing industry, transporting viscous and delicate products like jam demands precision, care, and equipment designed to handle unique challenges.

Traditional pumps often fall short when dealing with jam's complex properties, leading to inefficiencies, product damage, and costly downtime.

Bonve Pump Rotary Lobe Pump is engineered to overcome these limitations, offering unmatched performance for jam transfer while preserving quality and maximizing productivity.

Understanding Jam's Challenges

Jam is a high-viscosity, non-Newtonian fluid with distinct characteristics that complicate handling:

1.High Viscosity & Shear Sensitivity: Agitation or excessive shear force can break down jam's texture, causing separation of fruit solids and syrup.

2.Abrasive Particles: Fruit pulp, seeds, or sugar crystals can wear down pump components.

3.Sticky Residue: Sugar content leads to buildup, increasing clogging risks and hygiene concerns.

4.Sanitary Requirements: Compliance with food-grade standards (e.g., FDA, EHEDG) is critical to prevent contamination.

Why Traditional Pumps Fail with Jam

Centrifugal Pumps:

1.Struggle with high viscosity, leading to cavitation and energy waste.

2.High shear forces damage jam's structure.

Gear/Piston Pumps:

1.Susceptible to abrasion from particles, requiring frequent part replacements.

2.Dead zones trap residue, raising contamination risks.

Diaphragm Pumps:

1.Slow flow rates and pulsation may destabilize jam consistency.

2.Difficult to clean thoroughly, increasing downtime.

Bonve Rotary Lobe Pump Advantage

Designed specifically for thick, particle-laden fluids, Bonve Rotary Lobe Pump excels in jam handling with these innovations:

1. Gentle, Low-Shear Transfer

Progressive Cavity Design: Ensures smooth, pulsation-free flow to preserve jam's texture and prevent phase separation.

Precise RPM Control: Adjustable speed minimizes shear stress, ideal for shear-sensitive products.

2. Superior Handling of Particles & Viscosity

Robust Rotor-Stator Geometry: Handles solids (up to 40% particle content) without clogging or abrasion damage.

High Viscosity Tolerance: Efficiently moves jam (up to 2,000,000 cP) with minimal energy consumption.

3. Sanitary, Easy-to-Clean Design

Hygienic Construction: Made of FDA-compliant stainless steel or food-grade elastomers.

Quick-Disassembly Features: No hidden cavities or dead zones for fast CIP/SIP processes, reducing downtime.

4. Minimal Maintenance, Maximum Uptime

Wear-Resistant Materials: Long-lasting even with abrasive ingredients.

Seal-Free Operation: Eliminates leakage risks and seal replacement costs.

Preserve Product Quality: Maintain jam's signature texture, color, and taste.

Reduce Waste: No clogs, leaks, or product degradation.

Cut Operational Costs: Lower energy use, fewer maintenance stops, and extended pump life.

Meet Compliance: Full adherence to global food safety standards.

Upgrade to Bonve Rotary Lobe Pump

Whether you're processing strawberry preserves, mango jam, or citrus marmalade, Bonve Rotary Lobe Pump delivers reliability, efficiency, and gentle handling that traditional pumps can't match.

Say goodbye to downtime, wasted product, and compromised quality—experience the future of jam transfer today.

Contact Bonve Pump to schedule a consultation or request a product demonstration tailored to your production needs.

About Bonve Rotary Lobe Pump

Bonve offers the broadest range of its Rotary Lobe Pumps for food industry. As an excellent pump manufacturer, our hard technical barriers have become a powerful help for our Bonve pumps reform and innovation. So far, Bonve pumps have developed to the fourth generation and are mature.

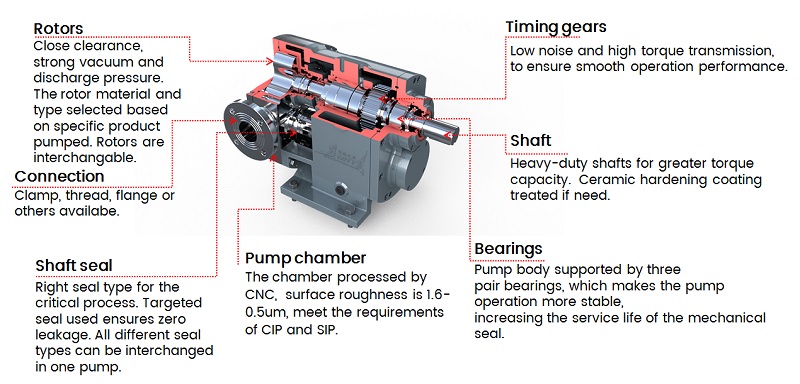

Interchangeable

· Interchangeable rotors, one pump multi-purpose.

· Targeted seal for specific application, ensure zero leakage.

Easy maintenance

· Compact structure, easy assembling and disassembling

· Maintenance in place, easy cleaning, CIPable and SIPable.

· Few wearing parts, low maintenance.

Long life

· All main parts proceed by CNC, high precision fabrication.

· No contact between the rotors, rotors and pump chamber.

· Six bearings with separate arrangement, high balance.

· Adjustable seal ring extends the shaft life.

· Axis key synchronous adjustment, no rotor collision problem.

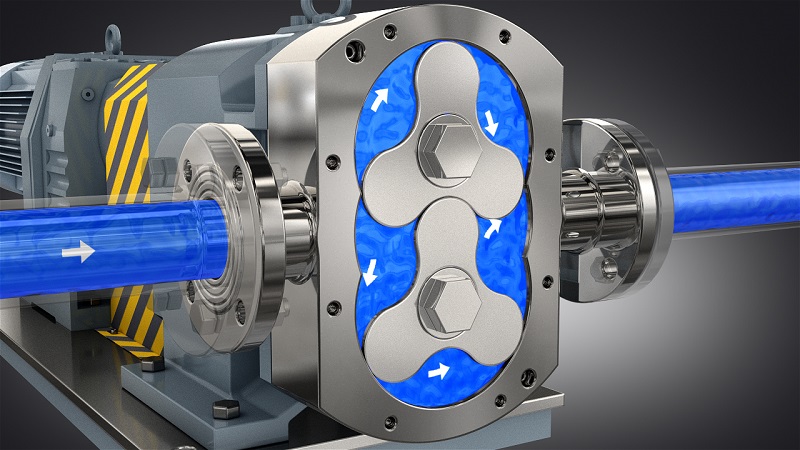

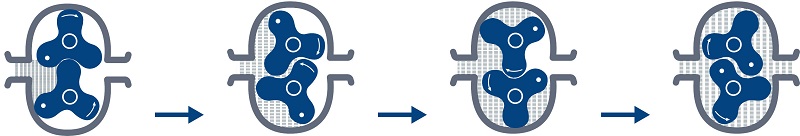

Working Principle

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

Bi-wing rotor diagram

Tri-lobe rotors diagram

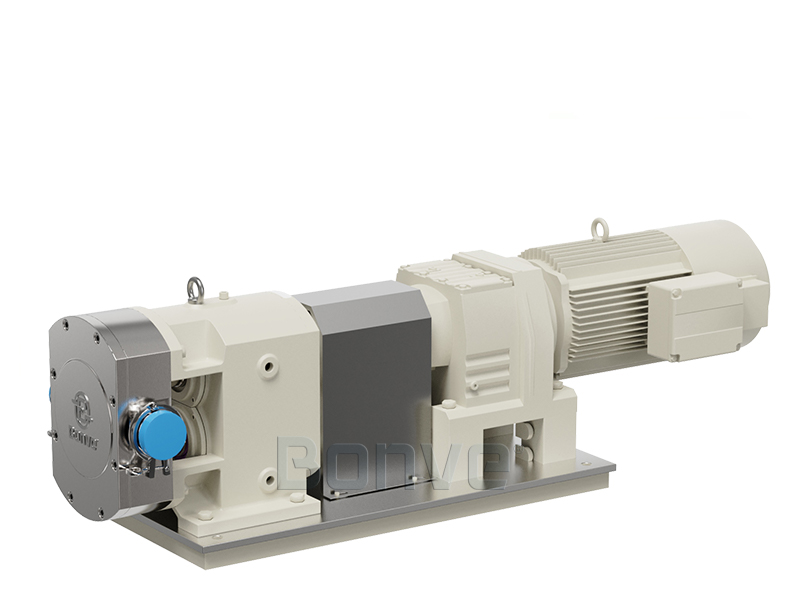

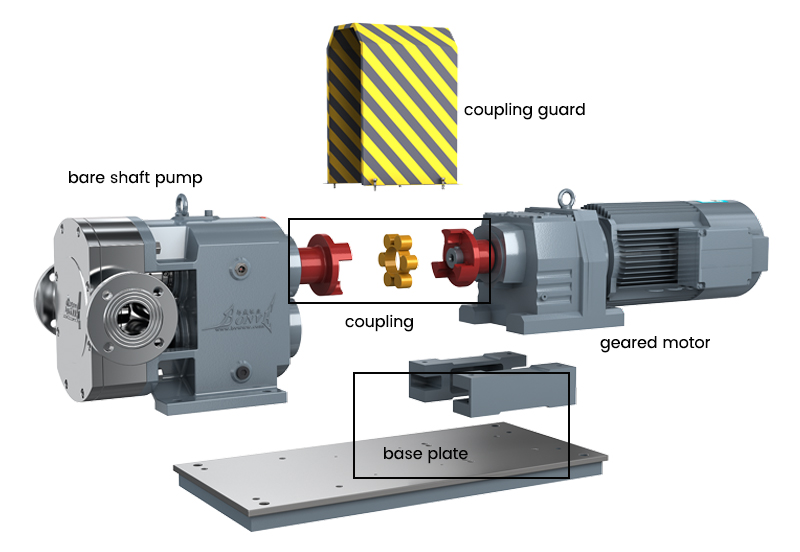

Main Parts of the Complete Pump

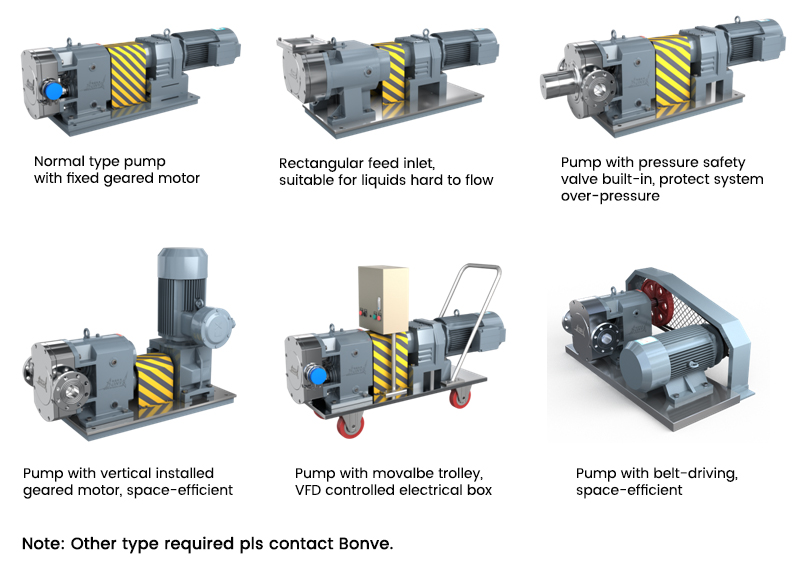

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and baseplae. With your order, bare shaft pump or complete pump is supplied.

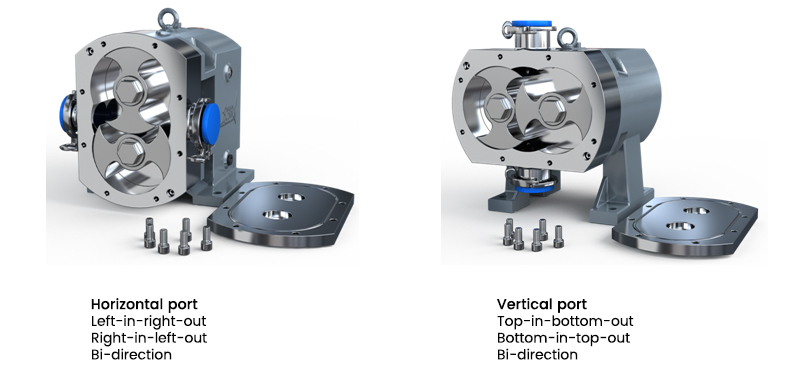

Bare Shaft Pump Structure

Based on the port direction, we have the pump with horizontal port and vertical port to meet your site installation.

Structure Details

Complete Pump Types

Technical Parameters

| Model | Displace -ment | RPM | Flow | Dis. Pre. | Power | Vacuum | Port size | Max viscosity |

|

| (L/r) | (r/min) | (m³/h) | (Mpa) | (kW) | (Mpa) | (mm) | (cp) |

| 25BV12-05 | 0.06 | 10-1000 | 0-0.5 | 0-1.2 | 0.37-1.1 | -0.080 | 25 | 1,500,000 |

| 40BV12-2 | 0.15 | 10-1000 | 0-2 | 0-1.2 | 0.75-2.2 | -0.080 | 40 | 1,500,000 |

| 50BV12-5 | 0.32 | 10-800 | 0-5 | 0-1.2 | 1.5-4 | -0.085 | 50 | 1,500,000 |

| 65BV12-10 | 0.65 | 10-600 | 0-10 | 0-1.2 | 2.2-7.5 | -0.085 | 65 | 1,500,000 |

| 80BV12-20 | 1.74 | 10-500 | 0-20 | 0-1.2 | 4-15 | -0.095 | 80 | 1,500,000 |

| 90BV12-30 | 2.60 | 10-500 | 0-30 | 0-1.2 | 5.5-22 | -0.095 | 100 | 1,500,000 |

| 100BV12-40 | 3.65 | 10-500 | 0-40 | 0-1.2 | 7.5-30 | -0.095 | 100 | 1,500,000 |

| 125BV12-50 | 4.60 | 10-500 | 0-50 | 0-1.2 | 7.5-37 | -0.095 | 125 | 1,500,000 |

| 140BV12-70 | 6.10 | 10-500 | 0-70 | 0-1.2 | 11-45 | -0.095 | 150 | 1,500,000 |

| 150BV12-80 | 7.63 | 10-500 | 0-80 | 0-1.2 | 11-55 | -0.095 | 150 | 1,500,000 |

| 200BV12-120 | 11.56 | 10-400 | 0-120 | 0-1.2 | 15-75 | -0.095 | 200 | 1,500,000 |

| 250BV12-150 | 14.22 | 10-400 | 0-150 | 0-1.2 | 18.5-90 | -0.095 | 250 | 1,500,000 |

| 300BV12-200 | 20.80 | 10-300 | 0-200 | 0-1.2 | 22-110 | -0.095 | 300 | 1,500,000 |

| 350BV12-300 | 32.60 | 10-250 | 0-300 | 0-1.2 | 45-160 | -0.095 | 350 | 1,500,000 |

| 400BV12-400 | 50.40 | 10-250 | 0-400 | 0-1.2 | 55-200 | -0.095 | 400 | 1,500,000 |

Note:

1. Tested medium: water. Your liquid's density, viscosity and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be varified according to different liquid properties.

3. Port size can be changed as needed.

Selection Guidelines

| Your Industry |

| ||

| About pump medium | Name: | ||

| Density (g/m³): | |||

| Viscosity (mPa.s): | |||

| Temperature (℃): | |||

| PH value: | |||

| Solid content (%): | |||

| Solid size (mm): | |||

| Suction side | Pressure: Positive ( ) bar; Negtive ( ) bar | How high (m): | |

| Suction pipe length (m): | Diameter (mm): | ||

| Bends (Pcs): | T-piece (Pcs): | Valves (Pcs): | |

| Discharge side | Pressure (Mpa): | ||

| Vertical delivery pipe length (m): Total delivery pipe length (m): | Diameter (mm): | ||

| Bends (Pcs): | T-piece (Pcs): | Valves (Pcs): | |

| Required flow rate (L/H) | Operating flow: | Max. flow: | |

| Pump material required | SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) | ||

| Motor required | Phase: Single ( ) Three ( ) | Voltage (V): | Frequency (Hz): |

| IP grade: | Energy efficiency: | Anti-explosive: | |

| Installation type | Fixed ( ) | Movable ( ) | Fixed with adjusting feet ( ) |

| Others |

| ||

About Us

BONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS. Providing its customers with customized pumping and mixing solutions and solving their problems during the production.

Bonve pumps and mixers are widely used in food, dairy, beverages, chemical, pulp&paper, soaps&detergents, pharmaceuticals, pesticide, coatings etc. By 2024, Bonve served 8,000+ customers in various industries and 100,000+ pumps running in the worldwide.

Time and again companies specify Bonve pumps as the "standard" equipment for their manufacturing processed. We are looking forward to be partner with you.

Contact Us

We welcome you to contact us for a pump solution if have any demand.

Contact person: Mr. Luke

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 13586591843

Email: bvsales3@bonvepumps.com